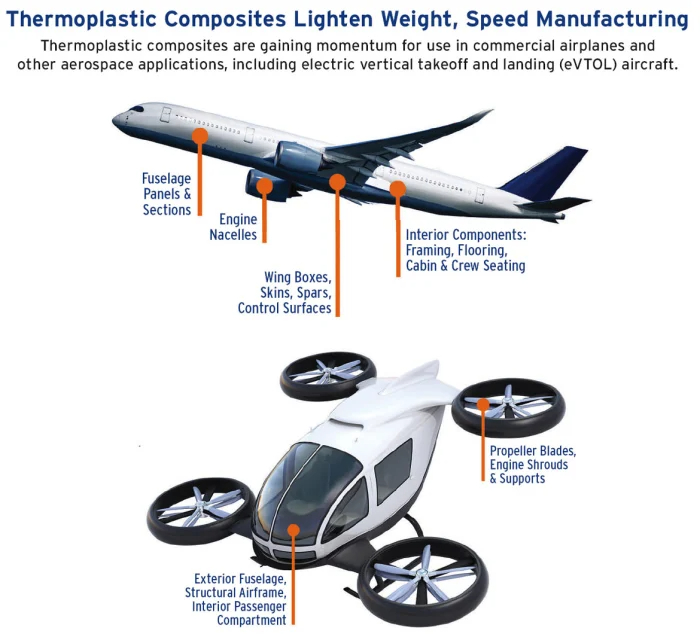

I nā makahiki i hala iho nei, ua ulu wikiwiki ka fiber-reinforcednā mea hoʻohui thermoplastic me nā resins thermoplastic ma ke ʻano he matrix, a aia ka piʻi ʻana o ka noiʻi a me ka hoʻomohala ʻana i kēia mau composites hana kiʻekiʻe ma ka honua holoʻokoʻa. ʻO nā composites Thermoplastic nā mea i hana ʻia me nā polymers thermoplastic e like me polyethylene (PE), polyamide (PA), polyphenylene sulfide (PPS), polyetherimide (PEI), polyether ketone (PEKK) a me ka polyether ether ketone (PEEK) ma ke ʻano he matrix a me nā ʻano like ʻole. nā pulupulu (e laʻa, nā ʻili kalapona, nā fiber glass, nā fiber aramid, etc.

Thermoplastic grease-based composites ʻo ia ka Long Fiber reinforced Thermoplastics (LFT), MT mau paʻi pre-impregnated a me ka moena aniani i hoʻoikaika ʻia Thermoplastics(CMT).

E like me ka hoʻohana ʻana i nā koi like ʻole, loaʻa i ka resin matrix PPE.PAPRT, PELPCPES, PEEKPI, PA a me nā mea ʻenehana ʻenehana thermoplastic ʻē aʻe.

Thermoplastic matrix

ʻO ka Thermoplastic matrix kahi ʻano mea thermoplastic me nā waiwai mechanical maikaʻi a me ke kūpaʻa wela e hiki ke hoʻohana ʻia i kahi ākea o nā huahana ʻoihana. Loaʻa i ka Thermoplastic matrix ka ikaika kiʻekiʻe, ke kūpaʻa wela a me ke kūpaʻa corrosion maikaʻi.

ʻO nā resins thermoplastic i hoʻohana ʻia i kēia manawa i nā noi aerospace ka nui o nā matrices resin kiʻekiʻe, me ka PEEK, PPS a me PEI, kahi amorphous PEI i hoʻohana pinepine ʻia i nā noi aerospace ma mua o semi-crystalline PPS a me PEEK, nona ka PEI amorphous. ʻoi aku ka nui o nā noi ma nā hale mokulele ma mua o ka semi-crystalline PPS a me ke kiʻekiʻe hoʻoheheʻe kiʻekiʻe PEEK ma muli o kona haʻahaʻa haʻahaʻa haʻahaʻa a me ke kumukūʻai hana.

ʻOi aku ka maikaʻi o ka resin Thermoplastic a me ke kūpaʻa kemika, ʻoi aku ka kiʻekiʻe o ka lawelawe ʻana, ka ikaika kikoʻī kiʻekiʻe a me ka paʻakikī, ʻoi aku ka maikaʻi o ka haʻihaʻi ʻana a me ka hoʻomanawanui ʻino, maikaʻi ke kūpaʻa luhi, hiki ke hoʻoheheʻe i nā geometries paʻakikī a me nā hale, adjustable thermal conductivity, recyclability, kūpaʻa maikaʻi i nā wahi paʻakikī. , hoʻoheheʻe hou ʻia, a me ka weldability, etc.

Huipuia i haku ʻia me ka resin thermoplastic a me ka hoʻoikaika ʻana i nā mea he nui nā pono e like me ka lōʻihi, ka paʻakikī kiʻekiʻe, ke kūpaʻa kiʻekiʻe a me ka hoʻomanawanui ʻino; ʻAʻole pono e mālama hou ʻia ka fiber prepreg ma kahi haʻahaʻa haʻahaʻa, palena ʻole ka manawa mālama prepreg; pōkole molding pōʻaiapuni, weldable, kiʻekiʻe huahana, oluolu e hooponopono; hiki ke hana hou a hoʻohana hou ʻia ka ʻōpala; ʻO ke kūʻokoʻa nui o ka hoʻolālā huahana, hiki ke hana ʻia i nā ʻano paʻakikī, hiki ke hoʻololi i ka hoʻololi ʻana, etc.

Mea hoʻoikaika

ʻO ka maʻamau, ʻo ka lōʻihi o nā fiber pōkole i hoʻoikaika ʻia he 0.2 a 0.6 mm, a no ka mea ʻoi aku ka nui o nā fibers ma lalo o 70 μm i ke anawaena, no laila ua like ke ʻano o nā pulu pōkole. Hana ʻia nā thermoplastics i hoʻoikaika ʻia i ka fiber pōkole e ka hui ʻana i nā fibers i loko o nā thermoplastics hehee. ʻO ka lōʻihi a me ka hoʻonohonoho pono ʻole o nā fibers i loko o ka matrix he mea maʻalahi ia e hoʻokō i ka pulu maikaʻi, a ʻo nā composite fiber pōkole ka mea maʻalahi loa e hana i ka hoʻohālikelike ʻia me nā mea lōʻihi a hoʻomau i ka fiber i hoʻoikaika ʻia, akā me ka liʻiliʻi o ka hoʻomaikaʻi ʻana i nā waiwai mechanical. Hoʻokumu ʻia nā ʻano huila pōkole i nā ʻāpana hope ma o ka hoʻoheheʻe ʻana a i ʻole nā ʻano extrusion no ka mea ʻoi aku ka liʻiliʻi o ka mana o nā pulu pōkole i ke kahe.

ʻO nā composites i hoʻoikaika ʻia i ka fiber lōʻihi ʻO ka maʻamau ma kahi o 20 mm ka lōʻihi o ka fiber a hoʻomākaukau ʻia me ka hoʻohana ʻana i nā fiber mau i hoʻokomo ʻia me ka resin a laila ʻoki ʻia i kekahi lōʻihi. ʻO ke kaʻina hana maʻamau, ʻo ia ke kaʻina hana pultrusion molding, kahi e hoʻomau mau ʻia ai ka hui ʻana o nā fibers a me ka resin thermoplastic e hana ʻia ma ka hohola ʻana i nā fibers ma o kahi make molding kūikawā. I kēia manawa, hiki i ka PEEK thermoplastic composites lōʻihi ke hoʻokō i nā waiwai i kūkulu ʻia ma mua o 200 MPa ma o ka paʻi FDM a me ka modulus ʻoi aku ma mua o 20 GPa, me ka hana ʻoi aku ka maikaʻi ma o ka hoʻoheheʻe ʻana.

ʻO nā fibers i loko o ka fiber reinforced composites "hoʻomau" a me ka lōʻihi o ka lōʻihi mai kekahi mau mika a i kekahi mau tausani mika. Hiki ke loaʻa nā hui fiber mau e like me nā laminates, prepreg tapes, a i ʻole braids, i hoʻokumu ʻia e ka hoʻokomo ʻana i ka matrix thermoplastic i makemake ʻia me nā fiber mau.

He aha nā hiʻohiʻona o nā mea hana i hoʻoikaika ʻia me nā fiber?

ʻO ka fiber reinforced composites he mau composites i hana ʻia e ka wili ʻana, ka hoʻoheheʻe ʻana a i ʻole ka pultrusion kaʻina o ka hoʻoikaika ʻana i nā mea fiber, e like me ke aniani fiber, carbon fiber, aramid fiber, etc., a me ka mea matrix. Wahi a nā mea hoʻoikaika like ʻole, ua hoʻokaʻawale ʻia nā composites maʻamau i hoʻohui ʻia i ke aniani fiber reinforced composites (GFRP), carbon fiber reinforced composites (CFRP) a me aramid fiber reinforced composites (AFRP).

Ma muli o kēia mau hiʻohiʻona o nā composites i hoʻoikaika ʻia i ka fiber:

(1) ikaika kiʻekiʻe a me ka modulus kiʻekiʻe;

(2) designability o ka waiwai waiwai;

(3) maikaʻi corrosion kū'ē a me ka lōʻihi;

(4) coefficient o ka hoonui wela e like me ko ke koki.

Hana kēia mau hiʻohiʻonaNā mea FRPhiki ke hoʻokō i nā pono o nā hale hou i ka lōʻihi nui, kiʻekiʻe, ke kaumaha kaumaha, ke kaumaha māmā a me ka ikaika kiʻekiʻe, a me ka hana ma lalo o nā kūlana koʻikoʻi, a hoʻokō pū i nā koi o ka hoʻomohala ʻana i ke kūkulu hale ʻenehana hou, no laila ua hoʻohana nui ʻia. i loko o nā hale kīwila like ʻole, nā alahaka, nā alaloa, ka moana, nā hale hydraulic a me nā hale lalo.

Kaomi maaneino ka ʻike hou aku e pili ana i nā mea hoʻohuihuiGRECHO Fiberglass

Ka manawa hoʻouna: Mar-31-2023